Personal Protective Equipment

PPE is usually considered a ‘last-resort’ in safety, as you should remove, reduce and isolate the risk instead. Fall protection PPE is divided into three categories, which are (in order of increasing risk):-

- Work restraint

- Work positioning

- Fall Arrest

Naturally, when planning your work you must try to use the safest practicable option, and the WAHR place specific demands on both employers and employees to select, maintain and use their fall protection PPE correctly. As with all personal safety systems, their effectiveness is an issue both of the design of the equipment and the ability of the worker to use it properly. The WAHR requires everyone using fall protection PPE to be trained, however the users may need to use different systems on occasion, and should also be familiar with the makes and models they use – so read the instruction books!

As soon as fall protection PPE (of any class) is used on a job, then some very important clauses of the WAHR apply:

- A minimum of two trained users must be on site

- All users must be trained in rescue from the PPE after an accident

- A pre-planned emergency procedure must be created

- All PPE must be inspected and maintained, with written records kept

- All anchor points must be suitable and sufficient

- Designated PPE anchors (bolts, wires, etc) need annual inspection

- Work must be minimised, both in risk and in duration

PPE: Fall Arrest

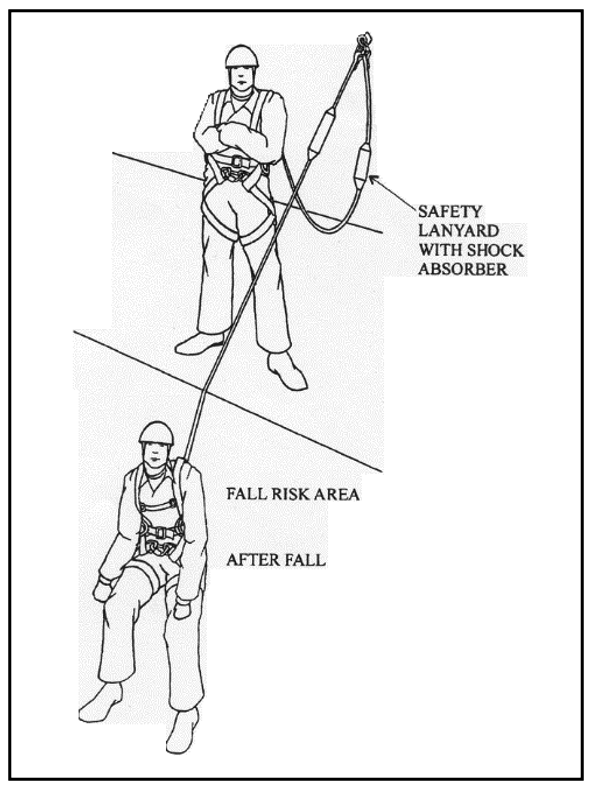

As the name suggests, fall arrest systems catch a worker AFTER they have PPE: Fall Arrest

As the name suggests, fall arrest systems catch a worker AFTER they have started to fall, and slow them down in a safe manner. They are usually unloaded before being ‘used’, and often have some slack. As a result, they must expect the user to have accelerated during the fall, and so they must dissipate their kinetic energy gradually to avoid injuring the user through high G-forces. They must also be strong enough to cope with these high forces, often many times more than the weight of the user. As such, fall arrest systems are highly controlled and must be planned and used with great care. There are many standards related to fall arrest equipment, the main ones being:

- EN361 – full body fall arrest harnesses

- EN354 – fall arrest lanyards

- EN363 – fall arrest systems

- EN353 – guided fall arrester systems

- EN355 – energy absorbers

- EN795 – anchor points

Fall arrest equipment is ‘single use’, so after a fall every item in the load chain (harness, lanyard, wire system, eyebolt, etc) must be either repaired or replaced. The usual criterion for ‘a fall’ is the activation of your shock absorber. Even items that show no obvious damage (such as a harness) must be replaced.

PPE: Work Positioning

Work positioning systems allow the user to be fully or partially suspended by their equipment. Even though they may be leaning over an edge, it is safer than using fall arrest alone as the system should prevent the worker from falling and shock-loading their PPE. Work positioning systems (lanyards, belts and harnesses) must comply with EN358 and be marked as such (or to an equivalent higher standard).

Work positioning systems cover all aspects of ‘loaded suspension’, from leaning gently on a belt to abseiling down a building – but this course specifically limits training to the use of work positioning for ‘partial support’. This means that without additional training you can use the systems to lean on or help provide balance, but cannot use them to support your full bodyweight.

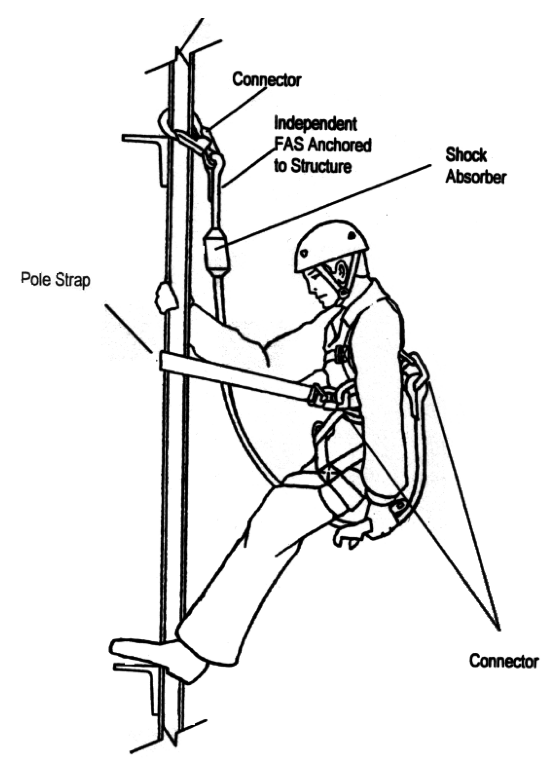

You cannot use a work positioning system without a second backup system.

This means that you must also use a system that will prevent or arrest a fall, should your primary work positioning system fail. This backup can be a second work positioning system or a fall arrest system, depending on the consequences of your primary system failure. In almost every case it must be a fall arrest system as work positioning systems cannot tolerate a shock-load. They are used to prevent a fall in the first place, and would fail (or cause critical injury) if used to arrest someone after they have started to fall, due to the high forces involved.

When working hands-free on a pole or mast, an EN358 padded belt and a pole strap are used. Great care must be taken to ensure a fall arrest system is used and will both protect the worker against a fall AND prevent the pole strap catching the energy of the fall first. As a result, the worker must also wear an approved fall arrest full-body harness.